The custom cutting sector of solar cells is gaining increasing relevance. This development initially emerged as a strategy to reduce production costs in the photovoltaic sector, but over time, the technology has advanced, offering greater flexibility and adaptability in creating customized products. Today, this technique is widely used for the production of mini solar panels, particularly useful for large-scale power supply of IoT devices.

Currently, cell cutting represents an effective solution for creating custom photovoltaic modules, meeting specific customer needs in terms of design, power, and cost. It is possible to work with monocrystalline or polycrystalline cells, with rear contacts, with 3, 4, 5 or more bus bars, and even in different colors. Thanks to precision laser technology, these cells can be shaped into almost any required form.

Based on the technical specifications provided by the client, we manufacture custom solar cells in any size and configuration. The use of high-precision laser machinery ensures an impeccable cut, with sharp edges and no imperfections. This is a crucial aspect for preserving the integrity of the solar cell's PN junction, minimizing the efficiency loss related to the cutting process. Additionally, the laser processing method ensures minimal material waste, thus optimizing production.

"MR WATT is capable of producing custom-cut solar cells in all formats obtainable from standard-sized Polycrystalline, Monocrystalline, or Sunpower solar cells. The cut can also be other than rectangular and square!"

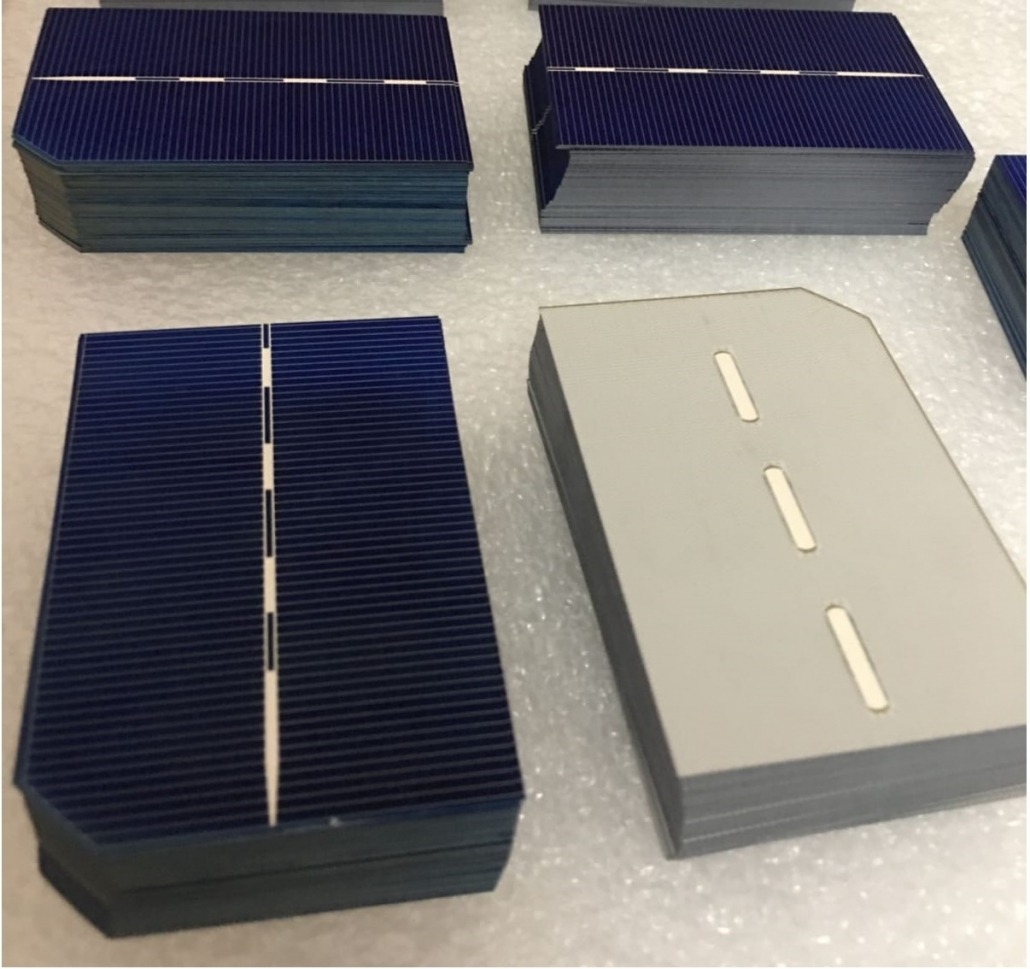

Below is an example of a customized cut of photovoltaic cells:

Small solar cells are used to create photovoltaic panels with higher voltages while maintaining the same surface area. After a solar cell is laser-cut, the voltage of each individual part remains the same as that of the original-sized solar cell, but the current produced will be proportional to the current of the original cells and linearly dependent on the cell's area. The larger the cell's area, the greater the current produced.

Below is an example of a solar panel with the same size and power but with different output voltages:

Solar panels of the same size with different voltages.

MR WATT is capable of producing custom-cut solar cells in practically all formats that can be obtained from standard-sized solar cells of 6"x6" (156x156mm) or 5"x5" (125x125mm) into smaller-sized solar cells. Most of the solar cells on the market today are made from either monocrystalline or polycrystalline silicon wafers. Among the monocrystalline cells, you can find the Sunpower semi-flexible solar cells, characterized by their high efficiency, semi-flexibility, and the fact that both poles are located on the back of the solar cell (back contact).

Taking as an example a classic polycrystalline or monocrystalline solar cell with dimensions of 156x156mm (6″x6″ inches), it can be cut without waste into smaller sizes, typically 3″x6″, 2″x6″, 1″x6″, 3″x3″, 3″x2″, 3″x1″ (measured in inches). The solar cells originally produced in a 6″x6″ format are available with 2, 3, 4, or 5 connecting lines known as bus bars (this does not happen with SunPower solar cells, which have the terminals only on the back), so the design of the cut cells can vary based on the placement of the strips on the solar cells. There are also monocrystalline solar cells measuring 125x125mm.

A different discussion is to be made for Sunpower solar cells (125x125mm and 161x161mm). These solar cells are characterized by having the terminals only on the back side and on opposite sides. This requires cuts to be made only in one direction and to have one side of the solar cell fixed at 125mm. Below we provide an example of a solar panel with the same dimensions and power but with different output voltages:

If you need custom-made solar cells, even special ones, don't hesitate to contact us and we will surprise you!

Below you can find more specific examples of possible cuts. As you will see, the possibilities are endless!